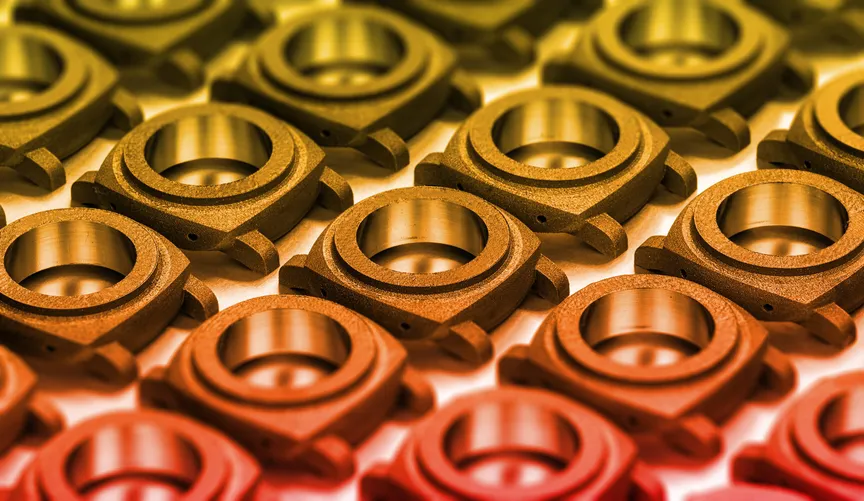

Titanium Metals Corporation Case Study

A Titanium Melting Plant Powered by On-site Solar and Storage Microgrid

Renewable Energy Sparks A Revival in Domestic Manufacturing

Titanium Metals Corporation is constructing a titanium smelting facility on a former aluminum smelting site in West Virginia. When operations starts in 2025, the new titanium facility will run primarily on renewable energy generated and stored by a microgrid located on the 2,000-acre site.

The Potential of On-site Energy Generation

The plant will include two types of electricity-driven furnaces to generate intense heat for melting sponge and scrap. When fully built, the microgrid will power the plant with 106 MW solar generation and 50 MW storage.

The solar-plus-battery system will provide the firm, reliable supply of power that melting furnaces require — and at a cost comparable to traditional power sources.

TIMET's Titanium Facility - A Model For Future Manufacturing Plants

Demonstrates the ability of a microgrid

to fulfill the needs of industrial clients, this includes providing renewable energy precisely when and where it is required and stimulating economic growth through manufacturing supported by clean energy.

On-site microgrid improves

the “time to power,” which is the amount of time it takes to build and connect renewable energy resources to the grid. Today, new energy projects are stuck in interconnection ques up to 5 years.

Clean & Cheap sources of electricity

can help revitalize the energy-intensive domestic manufacturing of titanium